Features:

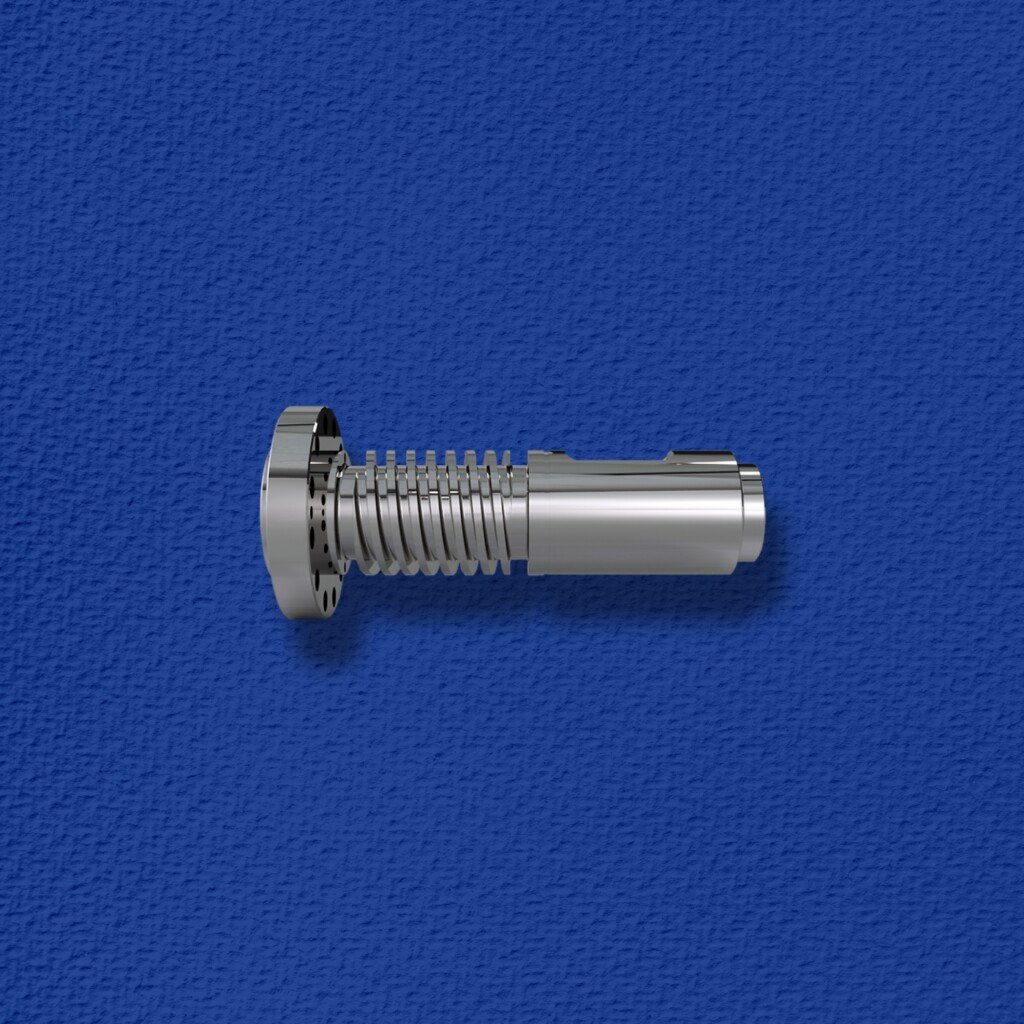

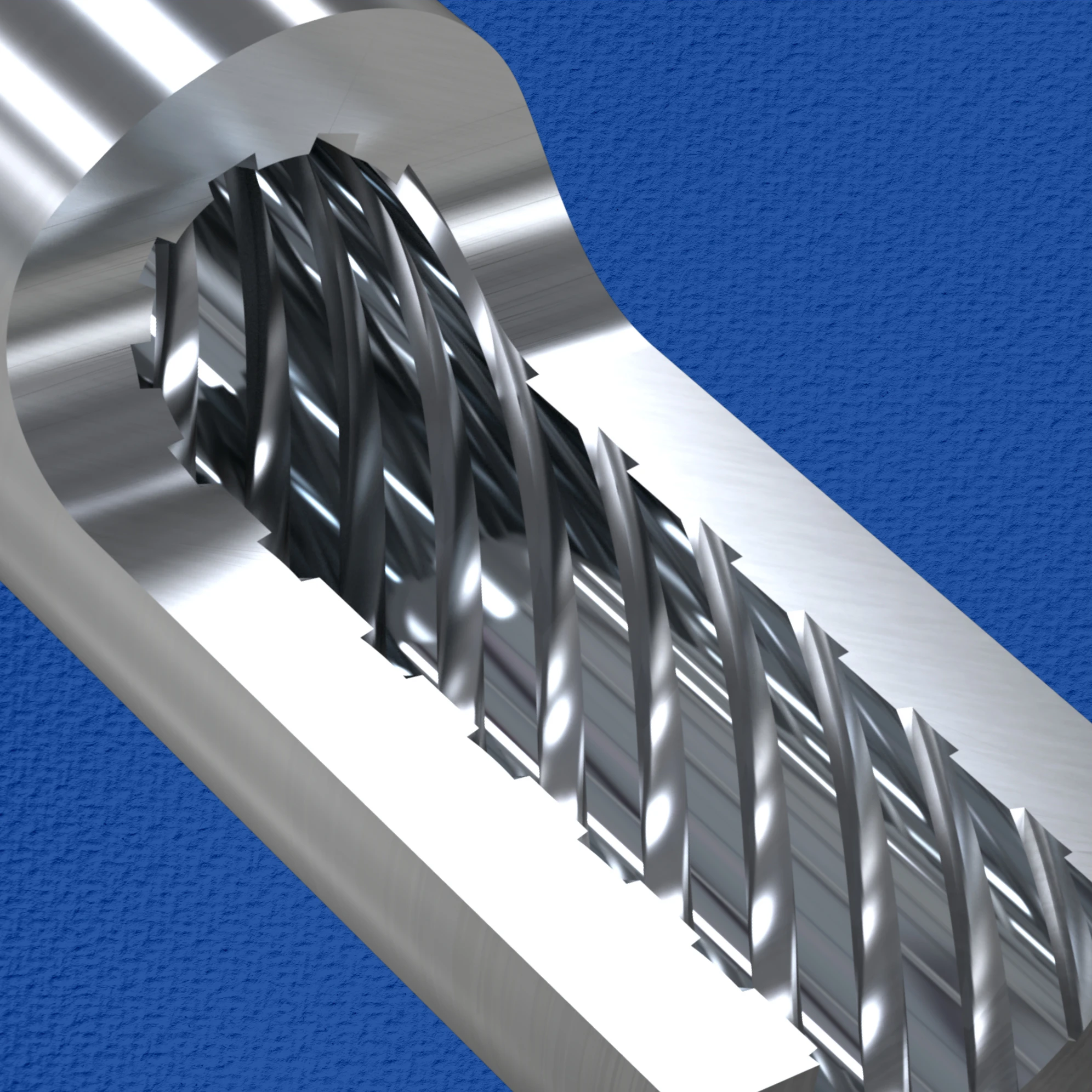

We provide Groove feed Sleeve for our barrel. Grove Feed ensures better melting due to increase shear and higher output capacity. We manufacture Groove Feed sleeve with diameter ranging from 35mm to 150mm.

- Base Material: D2, M2, EN41B (Musco Make)

- Surface Treatment: Gas/Ion Nitriding, Vacuum Hardening, Chrome Plating, Through Harden, Bimetallic Alloy Coating

- Nitriding Layer Depth: 0.5to 0.7mm

- Nitriding Skin Hardness: 62 to 65 HRC

- Bimetallic Coating Layer: 1.5to 2mm

- Bimetallic Coating Hardness: 65to 68 HRC

- Bimetallic Coating Alloy: Wc (Tungston Carbide), Ni, B, Cr

- Dimensional accuracy in tolerance ± 0.02 mm

- Certificate of base and coating material is given

- High Plasticizing performance and throughput

- Dimensionally accurate

- Easy to Install

Applications:

- Multi-Layer Film Plant (LDPE/LLDPE/HDPE/PP)

- Sheet Extrusion Machine (PP/LD/HD/ABS/PC/HIPS)

- Extrusion Coating Machine (LD/HD/PP)

- HDPE Pipe Plant

- Plastic Recycling Line

- Rubber Extrusion