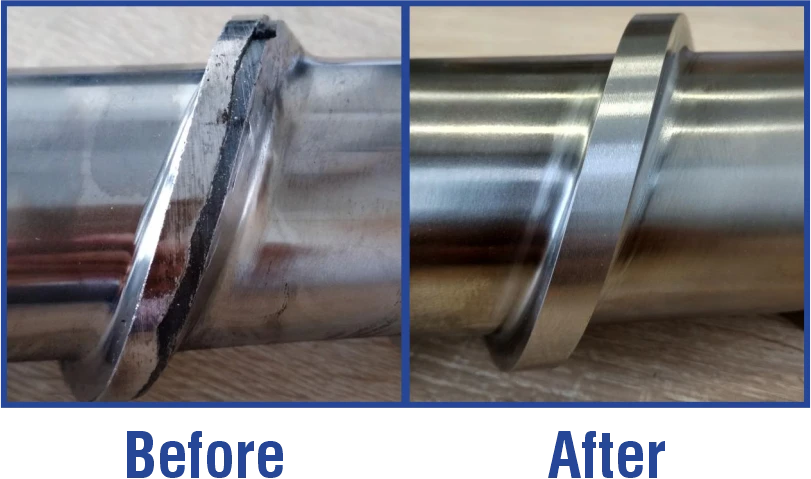

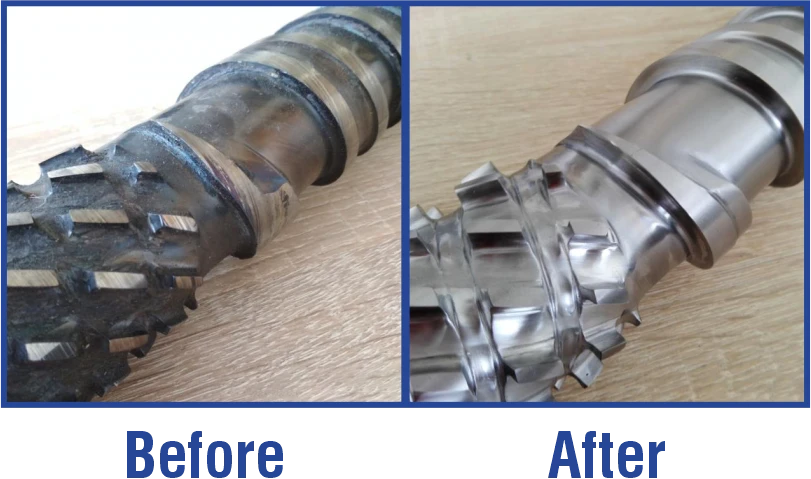

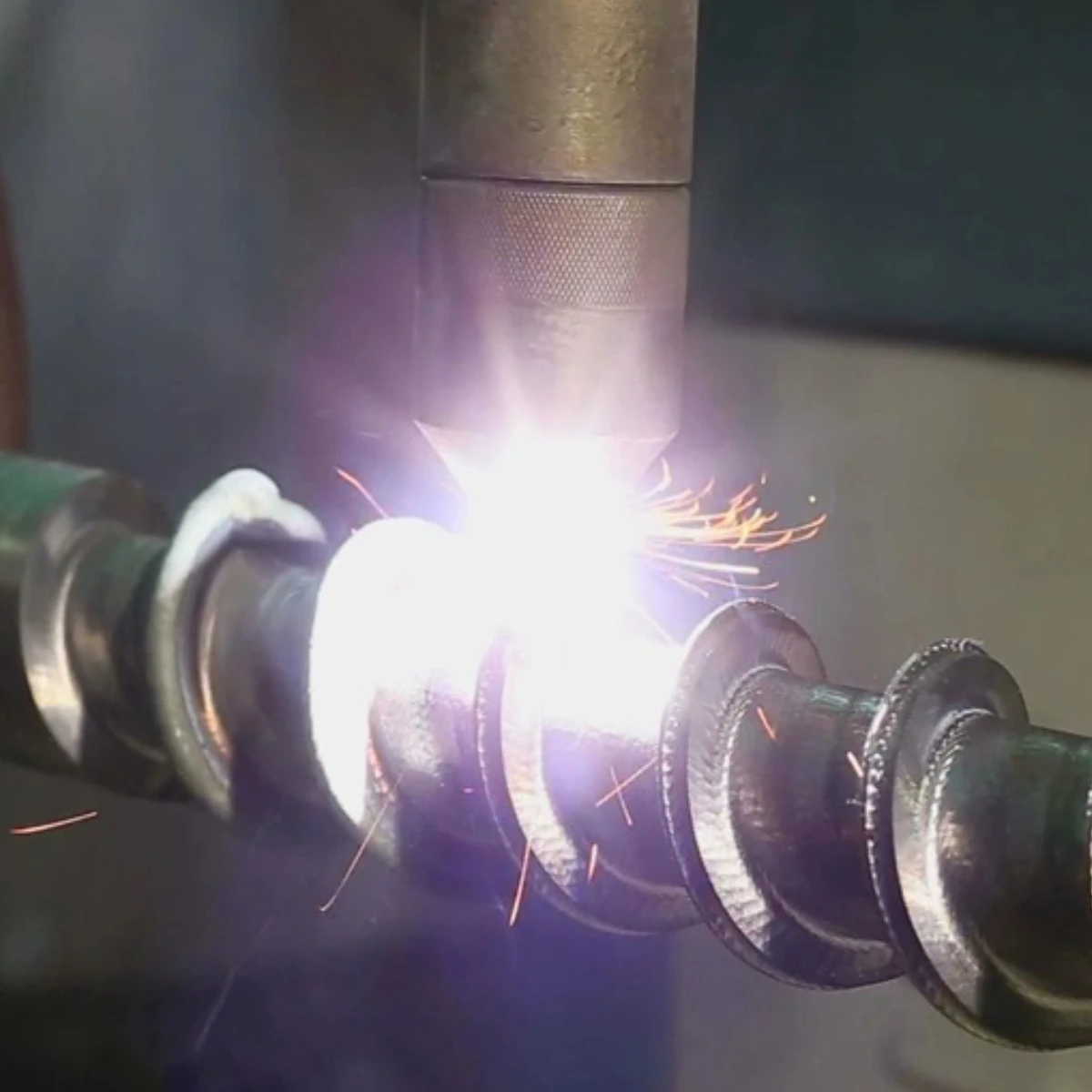

Screw Rebuilding Process:

Screw inspection & damage assessment | Ultrasonic test to check crack | Inspection report submit to customer | Even OD grinding for welding | Rebuild with hard facing rods | Flight side machining & grinding | Flight OD grinding | Bimetallic alloy coating | Flight OD grinding with diamond wheel | Polishing | Nitriding | Straightening | Grinding | De-crome | Polishing | Hard crome plating | Final griding | Polishing | Buffing | Final Inspection | Dispatch.

Barrel Refurbishing Process:

Barrel inspection | Ultrasonic test to check crack | Inspection report submit to customer | Barrel clean cut ID boaring & honning | Nitriding | Tool steel(D2, M2, H13) liner fitting | Honning | Final Inspection | Dispatch.