Features:

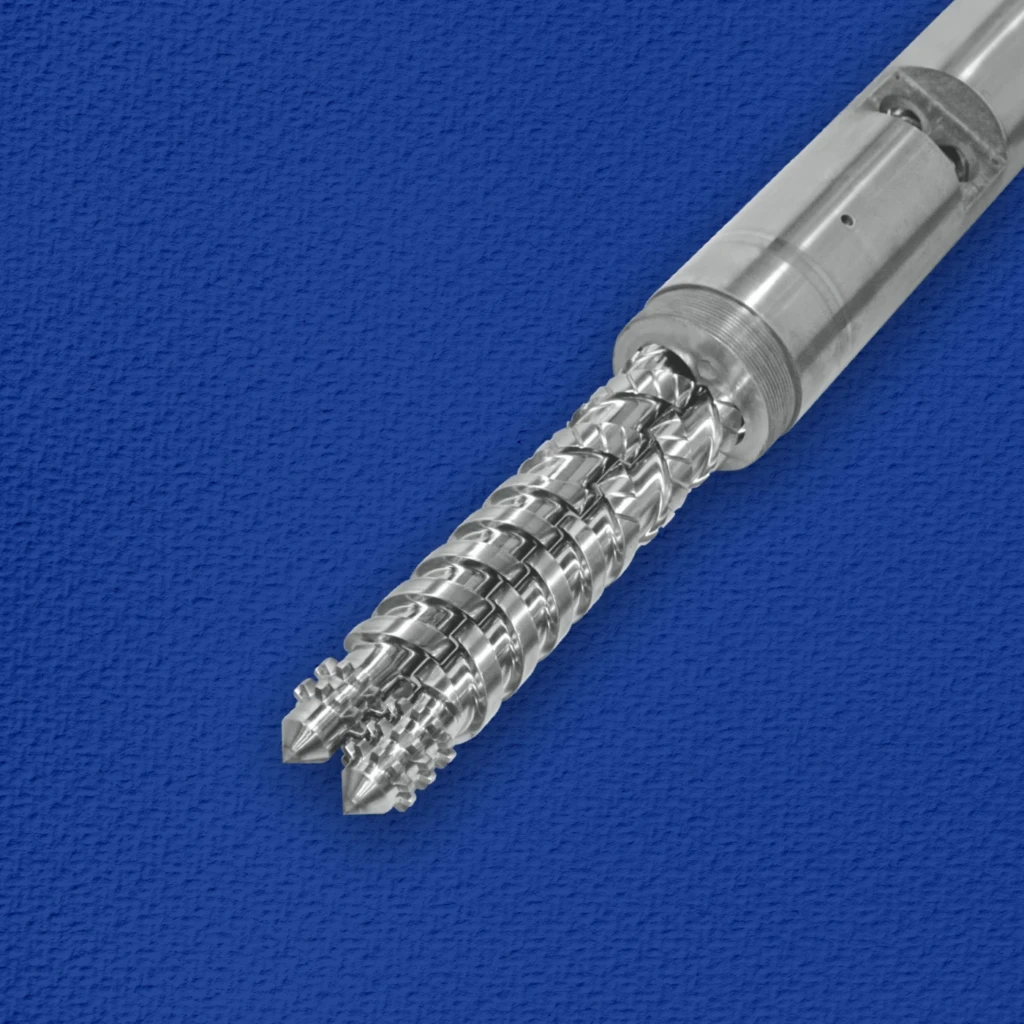

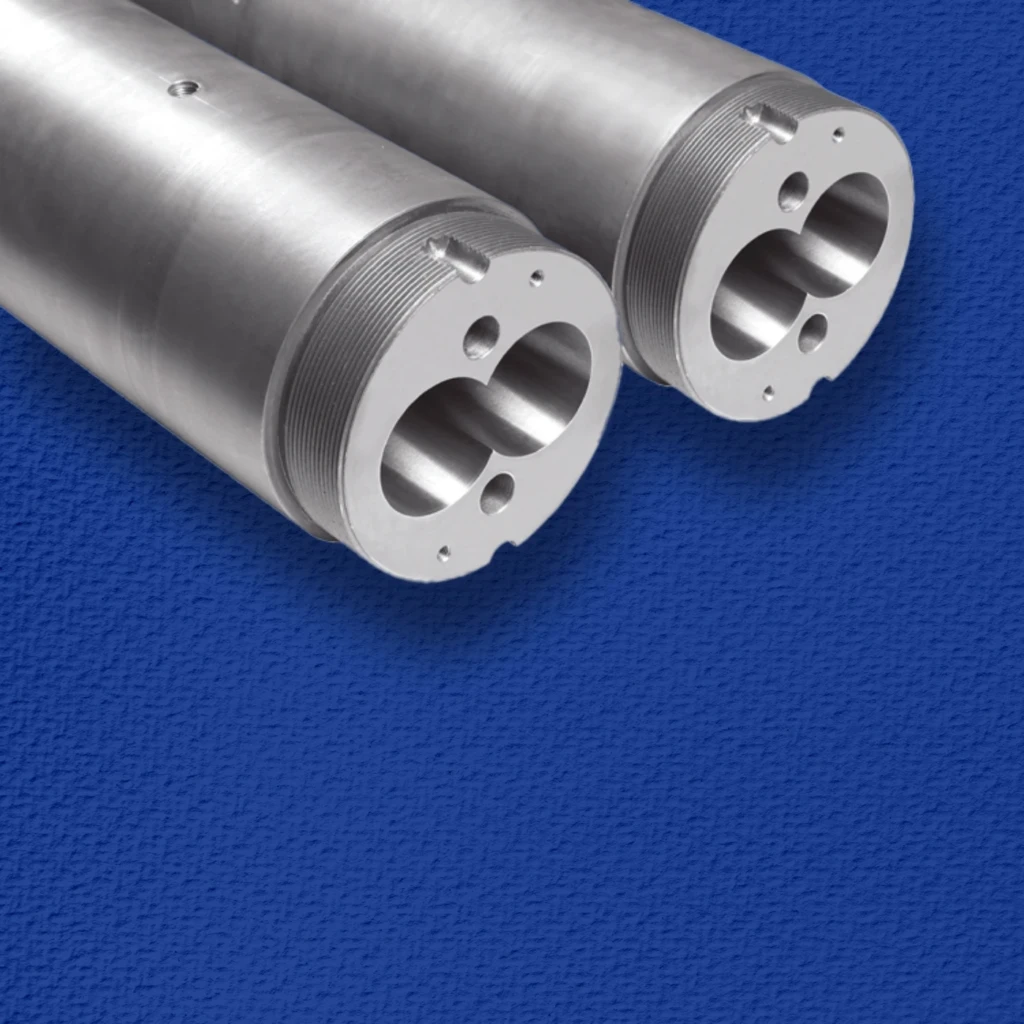

Parallel twin screw barrel is made for customers on OEM machines as well as end users for customers globally.

We manufacture a wide range of Twin Screw diameter ranging from 52mm to 110mm with output capacity ranging from 110 to 900 kg/hr.

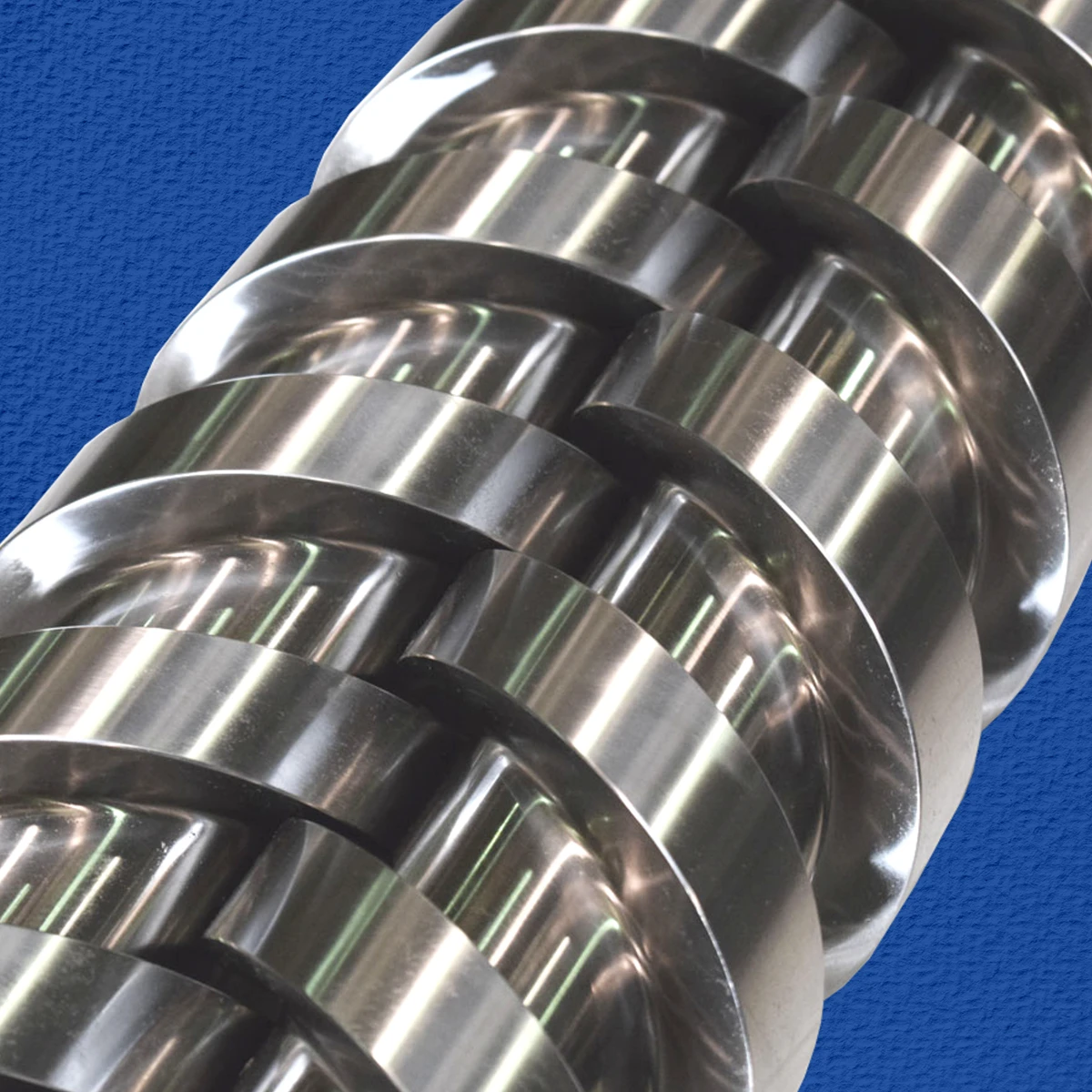

- Screw & Barrel Base Material: EN41B, D2, M2, H13, 17.4PH, AISI4340, AISI4140

- Surface Treatment: Gas/Ion Nitriding, Vacuum Hardening, Chrome Plating, Through Harden, Bimetallic Alloy Coating

- Nitriding Layer Depth: 0.5to 0.7mm

- Nitriding Skin Hardness: 62 to 65 HRC

- Bimetallic Coating Layer: 1.5to 2mm

- Bimetallic Coating Hardness: 65to 68 HRC

- Bimetallic Coating Alloy: Wc (Tungsten Carbide), Ni, B, Cr etc…

- Certificate of base and coating material is given

Parallel twin is critical on quality, the clearance between screws and barrels are very important.

Application:

- PVC Pipes

- PVC Profiles

- PVC Tube

- Form & Sheet

- Compounding

- Master Batch