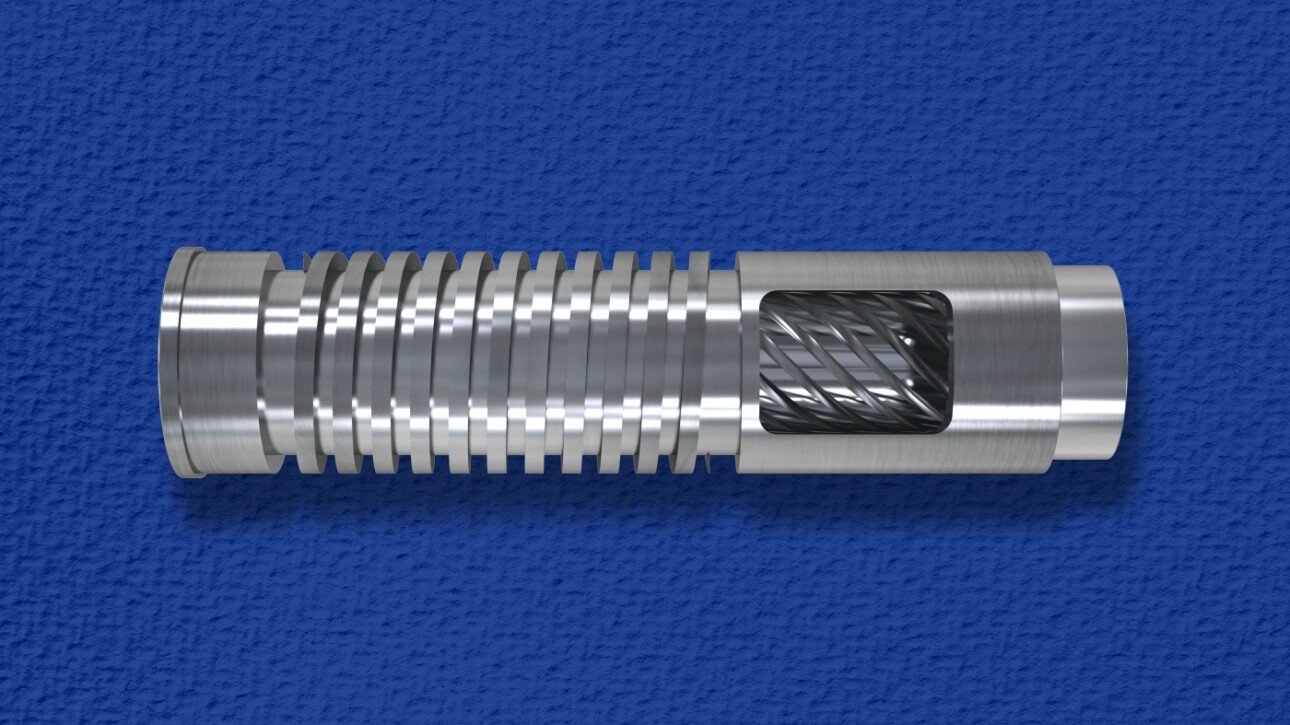

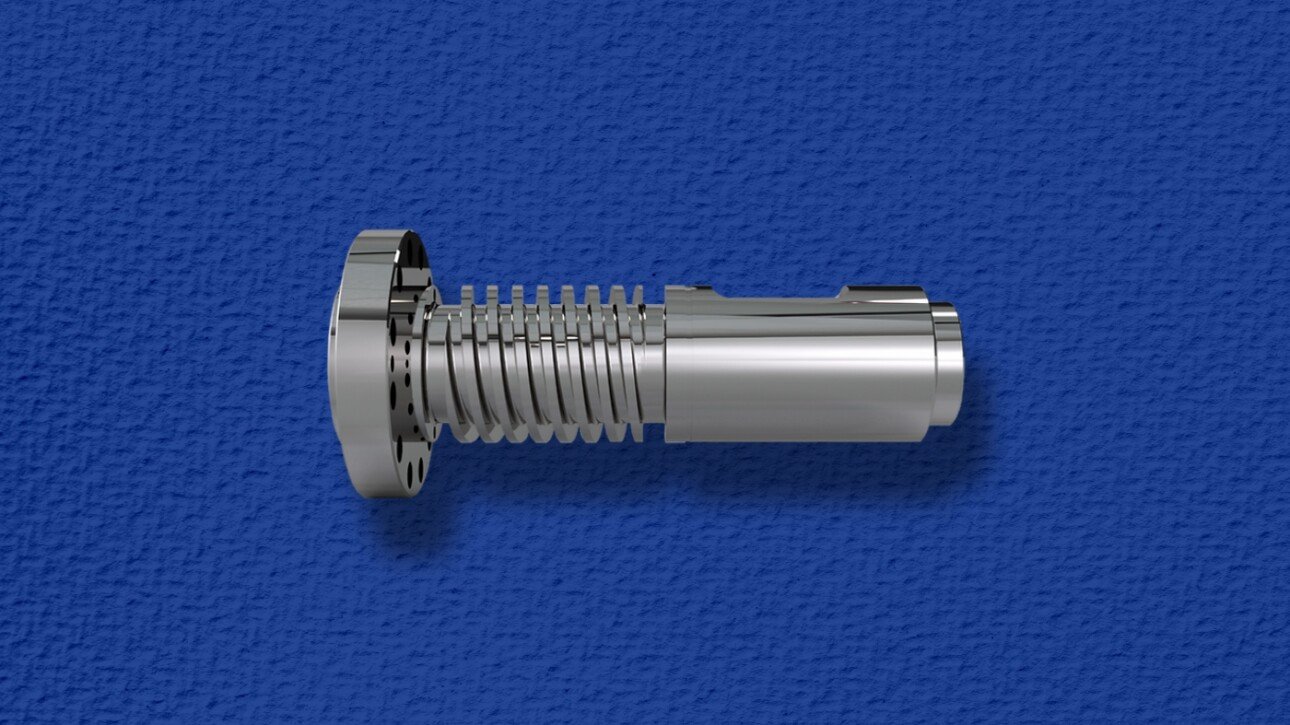

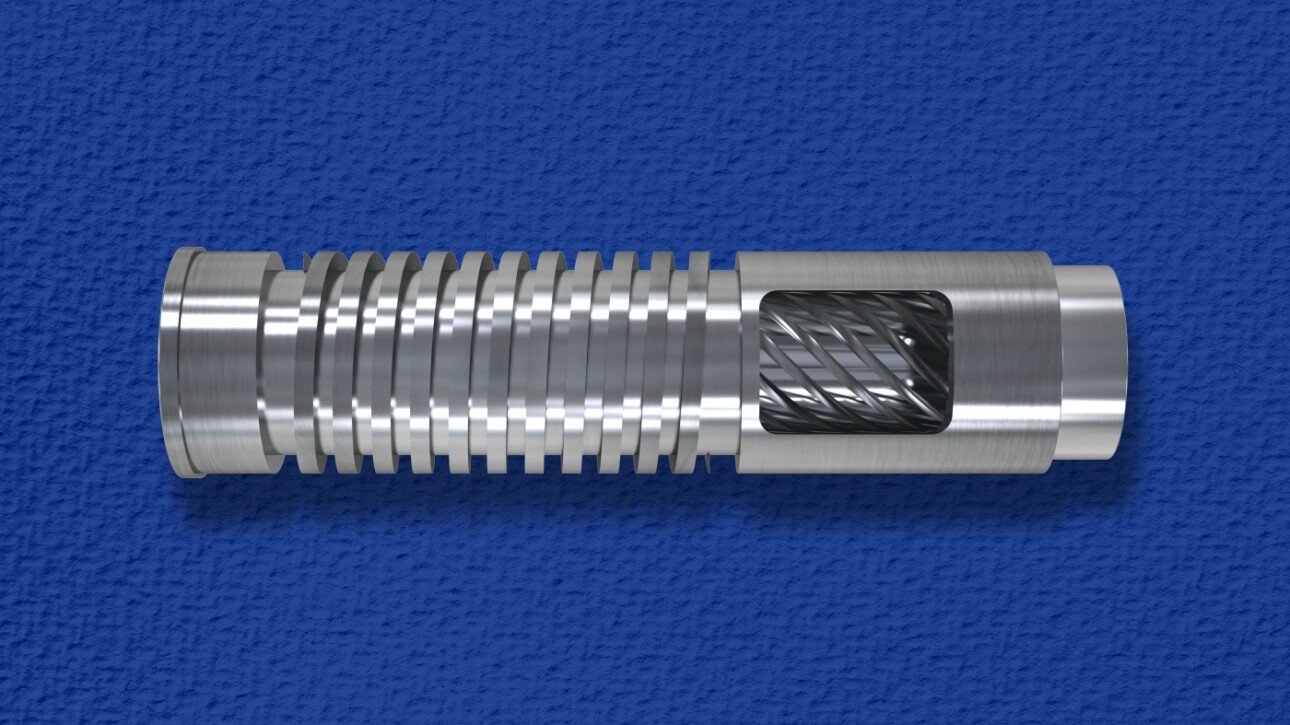

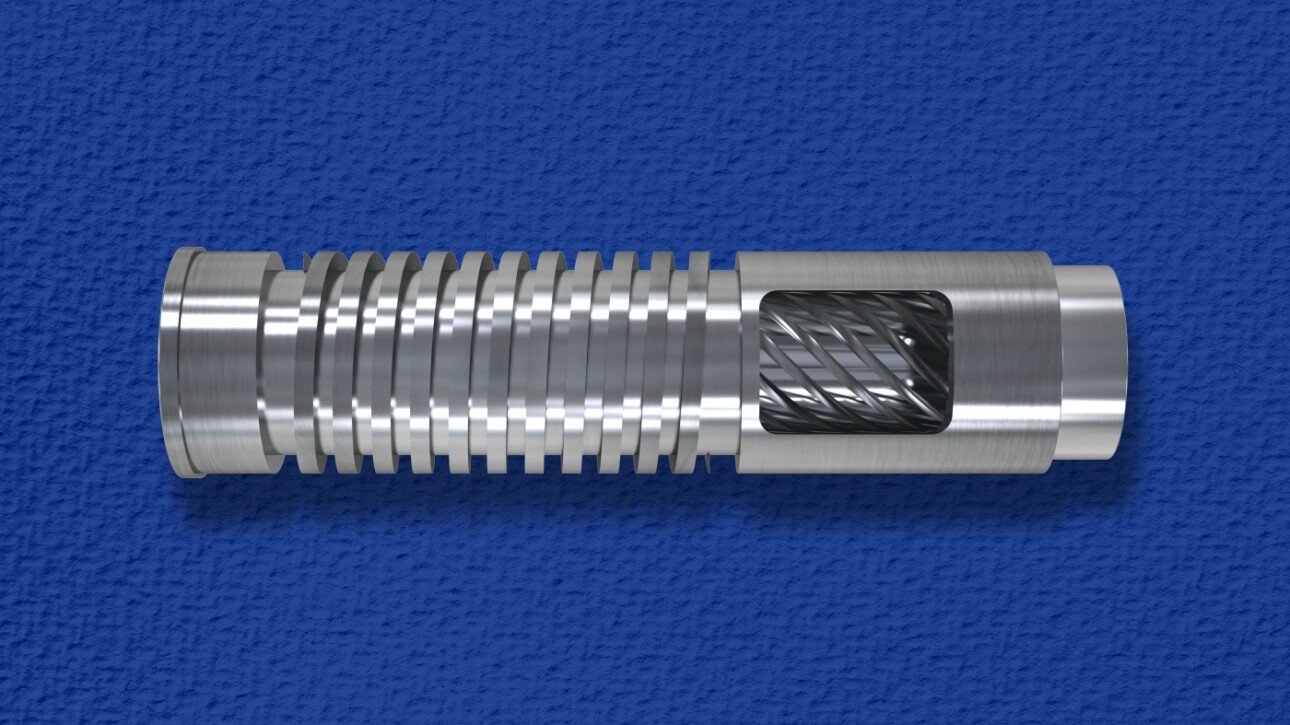

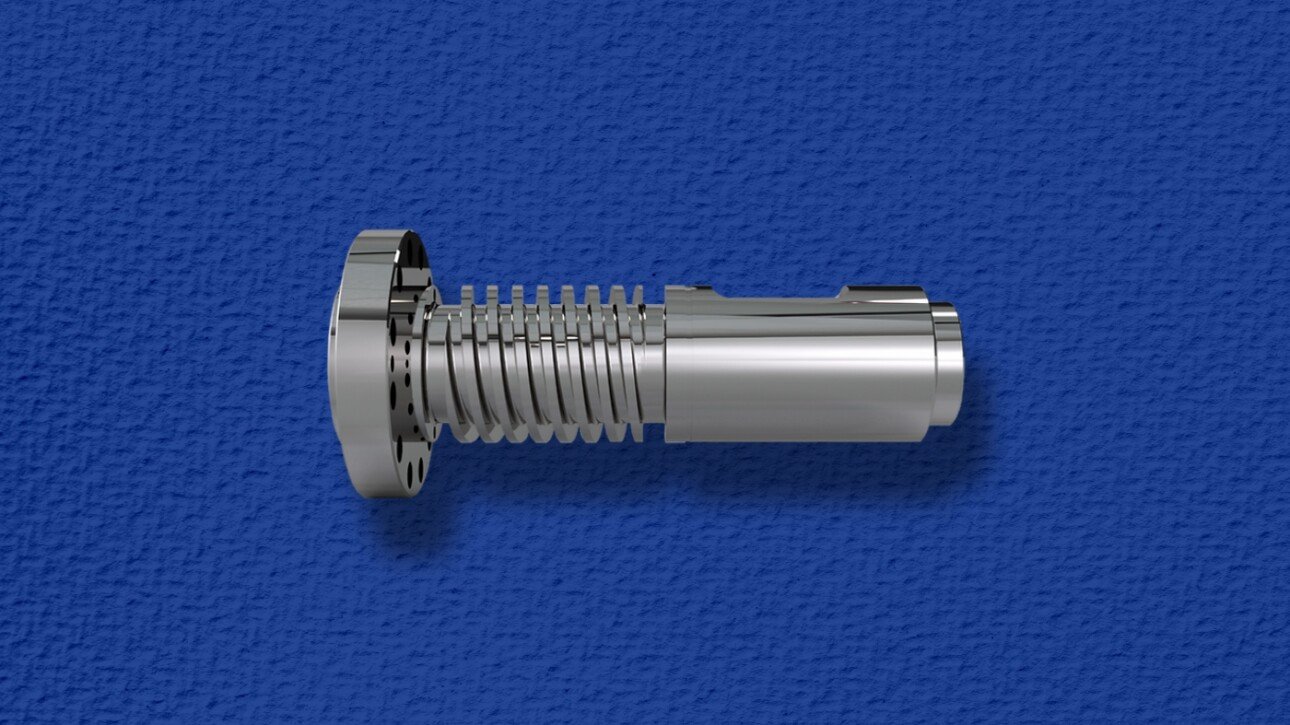

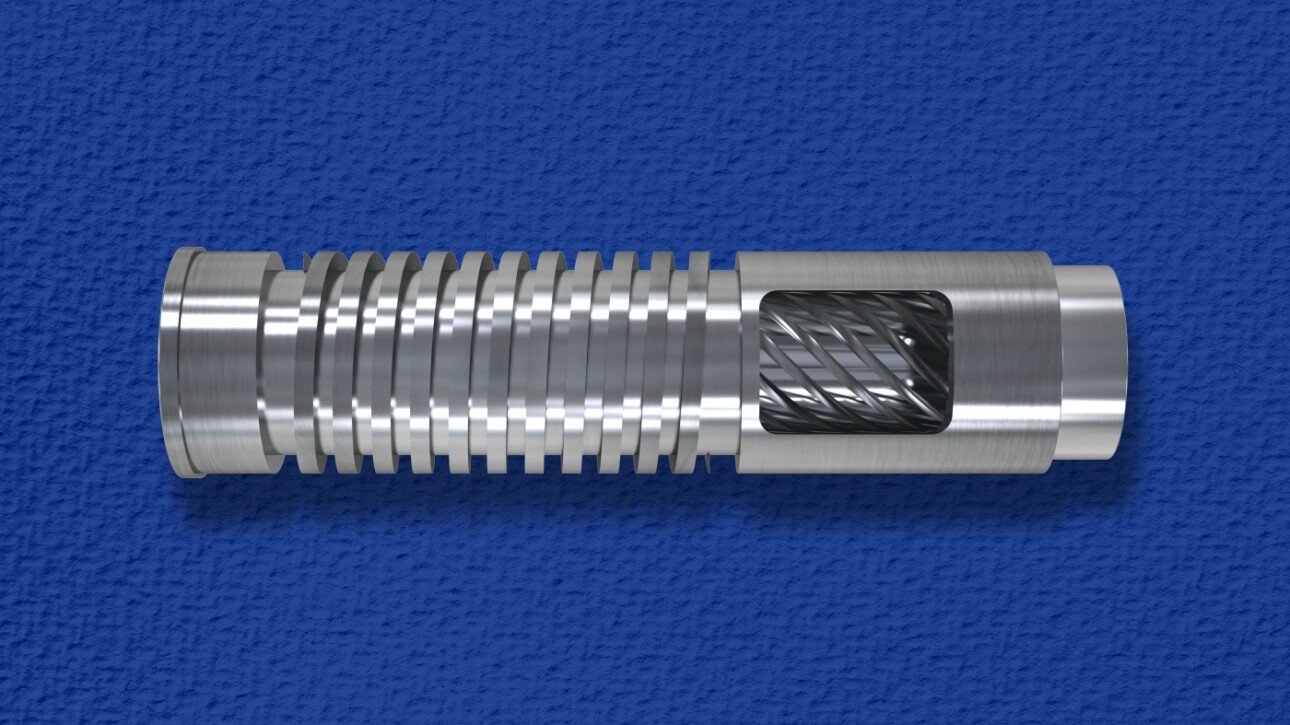

Groovefeed Screw & Barrel Sets is designed to enhance material intake, increase output rate, and improve processing stability in plastic extrusion applications. The grooved feed section allows better gripping of raw material, resulting in higher throughput and reduced energy consumption. This technology is widely used in recycling plants, pipe extrusion lines, and high-output plastic processing units.

Groovefeed screw barrel systems are ideal for processing HDPE, PP, PVC, and recycled plastics where consistent feeding and pressure control are essential. These systems improve melting efficiency, minimize slippage, and support high-speed production without compromising product quality. Industries focusing on productivity optimization and cost efficiency benefit significantly from groovefeed sets.